What is the Future of Laser Cutting Machines

With the development and widespread application of science and technology, the scope of sheet metal laser cutting processing is gradually expanding and gradually being carried out in our daily lives. According to institutional forecasts, the global laser processing market is expected to reach 9.75 billion US dollars by 2022, with a compound annual growth rate of 6.13% over a six-year period. At present, industries such as automobiles, clothing, shoemaking, and handicrafts are hotspots in the development of laser cutting machines, with several industries accounting for over 50% of the total.

The automotive industry has driven the growth of the laser cutting machine market

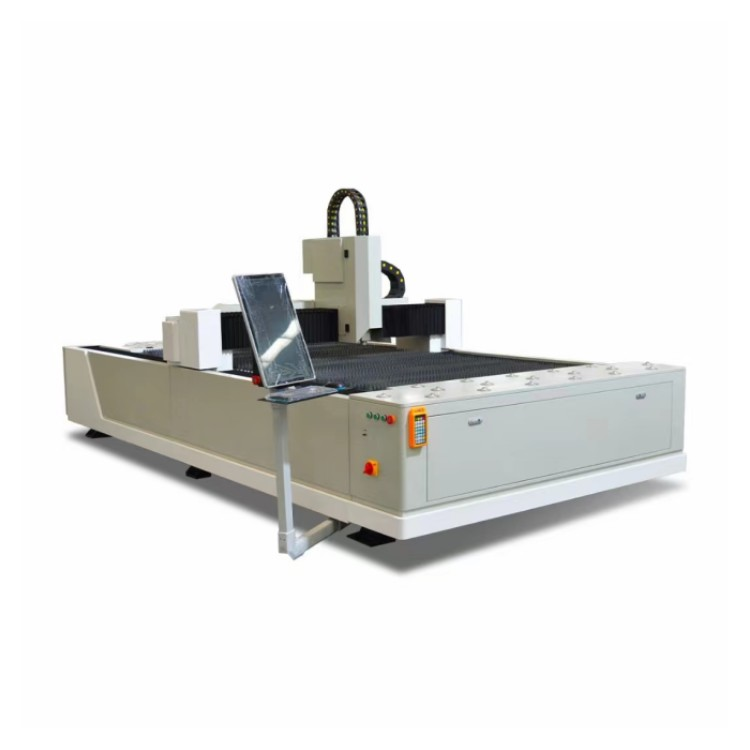

In the past few decades, the laser cutting industry has undergone a series of changes, including improvements in the quality and thickness of cutting materials, as well as improvements in machine power and efficiency. Today’s laser cutting machines can achieve higher speed, accuracy, and superior quality to efficiently process countless components and products, including automobiles, aerospace, healthcare, plastics, electrical and electronic, textiles, woodworking, and more.

The stable growth of the automotive industry is one of the core factors driving the global laser cutting machine market. In the past few years, there has been significant growth in automotive production capacity in Asian countries such as China and India. In recent years, the rapid development of industrial fiber lasers and disk lasers has also brought significant technological changes to traditional solid-state laser processing. Lasers will become the dominant trend in the global laser cutting machine market during the forecast period.

Intelligent manufacturing promotes technological upgrading.

Against the backdrop of the continuous deepening of “Made in China 2025″, laser technology is bound to drive the manufacturing industry to expand towards the high-end of the value chain. Among the ten key areas released in this strategy, the demand for high-end laser technologies such as laser welding, laser cutting, and 3D laser fusion printing will continue to be released in areas such as aerospace equipment and new energy vehicles.

According to the “Laser Industry Market Analysis Report” by the Prospective Industry Research Institute, in 2015, the total sales revenue of laser equipment (including imports) in industries such as industry, informatization, commerce, medical treatment, and scientific research in China’s laser industry market reached 33.6 billion yuan, an increase of 4.7 percentage points compared to 2014. In 2016, the annual growth rate of China’s laser industry reached over 20%. With the strong promotion of intelligent manufacturing by the Chinese government and the assistance of “Made in China 2025″, the industry continues to maintain rapid development.

In the process of transformation and upgrading, China’s economy has entered the “new normal” of medium to high speed development. Strategic emerging industries and productive service industries have bucked the trend and gradually become the two major “new engines” driving economic growth. More and more traditional industries rely on laser processing technology to improve the processing quality of products r solve problems that traditional processing methods and processes cannot solve, which brings good development opportunities for China’s laser industry.

The market capacity of laser cutting machines is quite large

According to the data monitoring center of the Prospective Industry Research Institute, in recent years, the laser cutting machine industry in China has developed rapidly, with an average annual growth rate of 30% for production and 22% for apparent consumption.

At present, the total annual demand for laser cutting machines in China is about 4 million units, accounting for about 15% of the total consumption, but still far below the world average of 25%. In addition, there is still a significant gap between China’s average consumption level and that of developed countries in the world.

As an important component of the industrial equipment field, laser cutting machines have been listed as one of the key technological fields for national development. Since 2010, China has successively introduced various policies to promote the development of the laser cutting machine industry.

At present, industries such as automobiles, clothing, shoemaking, and handicrafts are hotspots in the development of laser cutting machines, with several industries accounting for over 50%.

The application of laser cutting machines in the clothing industry began in the 1980s and has a history of over 20 years. With the development of clothing towards high-quality, new styles, and material saving, higher requirements have been put forward for laser cutting machines. Due to the fact that laser cutting machines have more advantages than manual cutting, other mechanical cutting, and electric cutting, processing a product can save 10% of material and reduce power consumption by 16% -18%. Therefore, using laser cutting machines can reduce product costs, achieve energy-saving effects, and have better product quality.

High power laser cutting machines are the future development trend.

With strong technological strength in China, the cutting quality, effectiveness, and cost of high-power laser cutting machines have greatly improved. It has been widely used in many industries in China, especially in furniture, advertising, hardware, electronics, and other industries. The planar cutting, drilling, cutting, carving and other processes of high-power laser cutting machines are all developing towards personalized cutting. It is necessary to use a computer control system, which can freely draw any shape and complete the cutting of various complex and fancy patterns. The operation is simple and the cutting effect is accurate. The future application in the processing industry will generate greater market demand.

Post time: Sep-22-2023