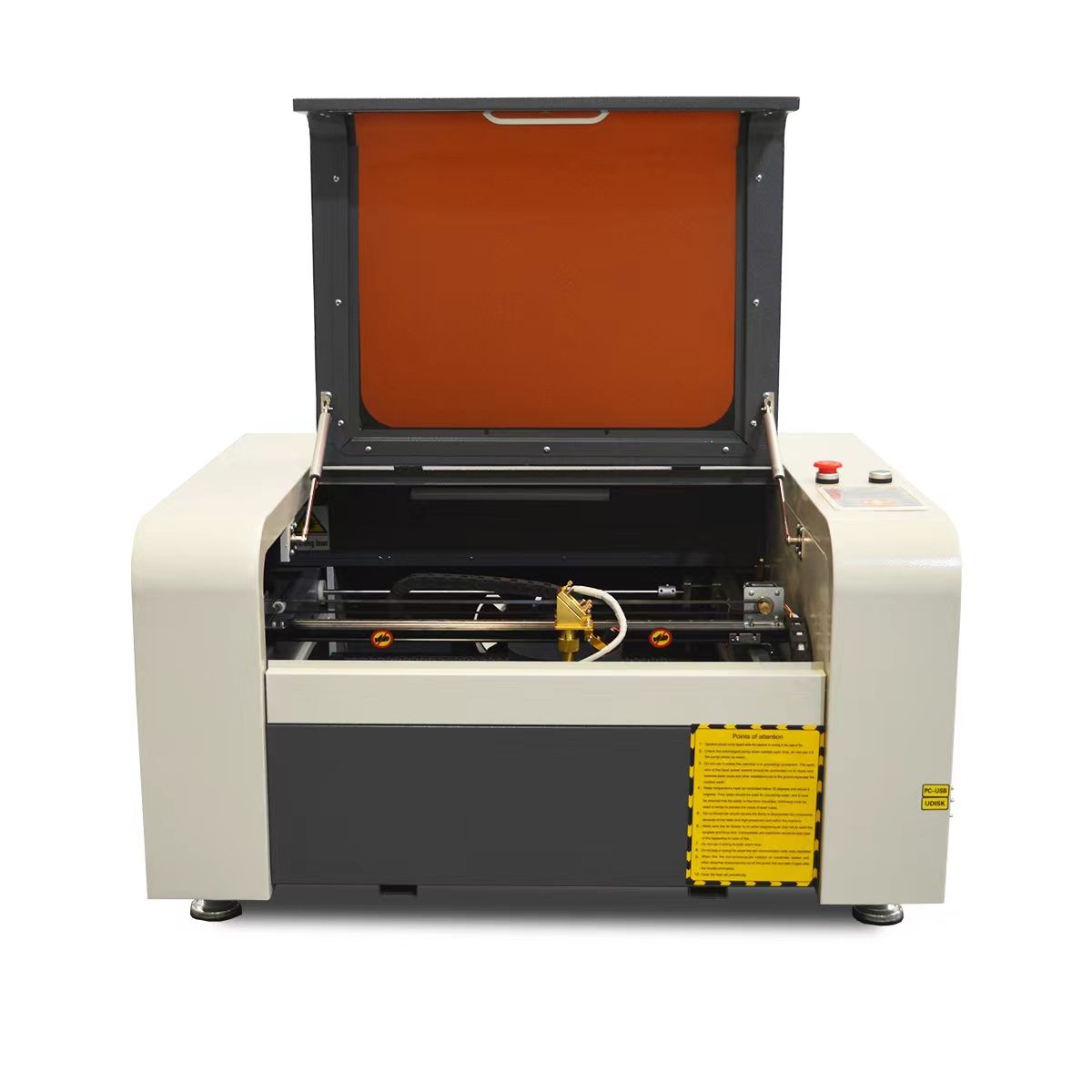

1325 Laser cutting machine

|

Model |

EC-1325 |

|

Work area |

1300*2500mm |

|

Machine size |

3200*2050*1130mm |

|

Machine weight |

900KG |

|

Application |

Advertising industry, woodworking industry, lighting engineering, LED advertising characters, furniture manufacturing, craft products, signs, packaging, architectural models, industrial molds, decoration, clothing, textiles, leather, industrial fabrics and many other industries |

|

Cutting material |

It can cut and engrave non-metallic materials such as acrylic, two-color board, wood board, MDF, leather, paper, cloth, etc.; it can also engrave glass and stone |

|

Laser power |

80W,100W,130W,150W,180W,300W,500W,600W |

|

Power /Mark and Peak |

Acrylic |

Wood |

MDP |

|

80 ~ 100w |

10mm |

10mm |

5mm |

|

100 ~ 130w |

15mm |

12mm |

6mm |

|

130 ~ 150w |

18mm |

15mm |

8mm |

|

150 ~ 180w |

20mm |

20mm |

10mm |

|

300w |

26mm |

25mm |

15mm |

( Reminder: If you want to use it for engraving, it is recommended to choose a low-power laser tube)

|

Working voltage |

AC 220V±10%,50HZ |

|

Control system |

Ruida、Qiancheng System DSP control,Can connected to a computer or offline USB can be used. |

|

Drive |

Raytheon stepping motor high subdivision drive |

|

Guide way |

Taiwan Hiwin Linear guide way |

|

Table |

Blade or honeycomb platform |

|

Transmission mode |

Synchronous belt drive |

|

Laser type |

Weiju sealed glass co2 laser tube wavelength 10.6μm |

|

Laser tube cooling |

Pure circulating water cooling |

|

Energy adjust |

0-100% stepless control、adjustable inside 0-100% can adjust |

|

Positioning accuracy |

≤±0.05mm |

|

Engrave speed |

0-1200mm/s |

|

Cutting speed |

0-600mm/s |

|

Minimal Formed Words |

Chinese characters 1.5mm English letters 1mm |

|

Work environment |

Temprature 0-45℃ humidity 5%-95%(no condensation) |

|

Whole machine power |

<3KW |

|

Software Support Format |

PLT、DXF、AI、BMP、RLD ,AutoCAD、CorelDRAW direct output |

|

1 |

Square tube welding, heavy-duty bed, finishing treatment by CNC machining center, |

|

2 |

Integrated beam transmission is more stable |

|

3 |

0.25 filament optical mirror frame, more stable optical path |

|

4 |

Y-axis pressure belt transmission, balanced force and reduced belt vibration |

|

1 |

Square tube welding, heavy-duty bed, finishing treatment by CNC machining center, |

|

2 |

Integrated beam transmission is more stable |

|

3 |

0.25 filament optical mirror frame, more stable optical path |

|

4 |

Y-axis pressure belt transmission, balanced force and reduced belt vibration |